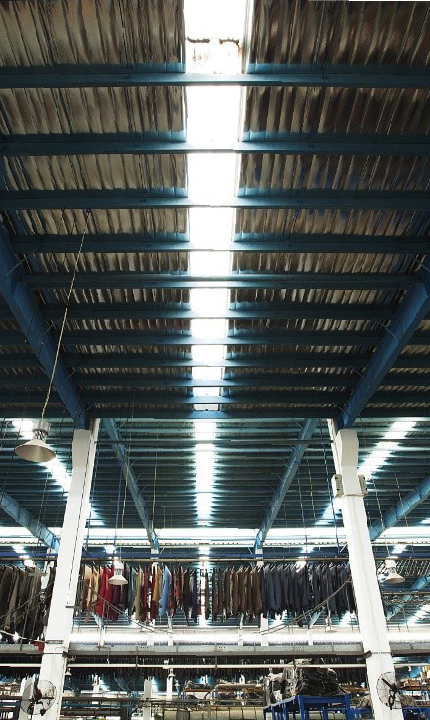

The concept started with a vision of our company and the requirements from brands to offer environmentally friendly Leather. LITE was born to provide our customers with the knowledge of carbon and water footprint usage for each of the leathers we create; giving customers the ability to choose the product that is the most environmentally-friendly, and with the lowest footprint. The LITE system is fully integrated into our manufacturing process, which is specially designed to reduce and control water and energy usage, as well as to reduce the amount of chemicals we use in the process. The effort we make is consistently minimizing our impact to the environment.

Featuring these and many more

- The thickness of the articles being covered in the calculator is ranged from 1.6mm-2.0mm

- The above calculator covers the saving data of the top ISA articles in 2022, please kindly contact our dedicated sales representatives for other articles

- The calculation is made based on the LITE Index Calculation Methodology

Restricted Substances List (RSL)

Our Restricted Substance List (RSL) is an integral part of our commitment to product safety. As one of the leading sustainable material manufacturers, we continue to make significant investments into the ongoing research of chemicals that are known or suspected to be harmful to the environment. In order to guarantee best practices, we have built our own “ISA Restricted Substance Management System”. This includes a comprehensive database with all of the chemicals we believe could be problematic in the future.